START

FINISH

Summary

This project aimed to establish deep ripping guidelines for growers on Mallee sandy soils. It was found that adequate soil loosening is a primary consideration for optimum outcomes.

The best deep ripping results were achieved by ripping to a depth of 45 centimetres using tynes spaced 50cm to 75cm apart. Fitting wings to the tynes and inclusion plates to aid topsoil burial improved loosening and mixing for best results.

Post-ripping trafficability can impact sowing, soil stability and machinery safety. Rolling was found to stabilise the soil to improve machine performance and crop consistency.

Background

Deep ripping ameliorates sandy soils by loosening compaction layers, incorporating topsoils and raising deeper nutrients into the root zone. However, the diversity of methods can lead to growers making substantial investments in equipment, time and machinery costs without achieving optimal results or, worse, negatively impacting the operation or productivity of their farm.

Research Aims

The core objectives of the project were to establish techniques for increasing productivity and groundcover on deep sandy soils (dunes) in the Mallee regions through deep ripping.

In The Field

Five demonstration sites were established over three years to determine the effectiveness and benefits of soil loosening, the benefits of adding organic amendments, and the importance of consolidating soil after ripping.

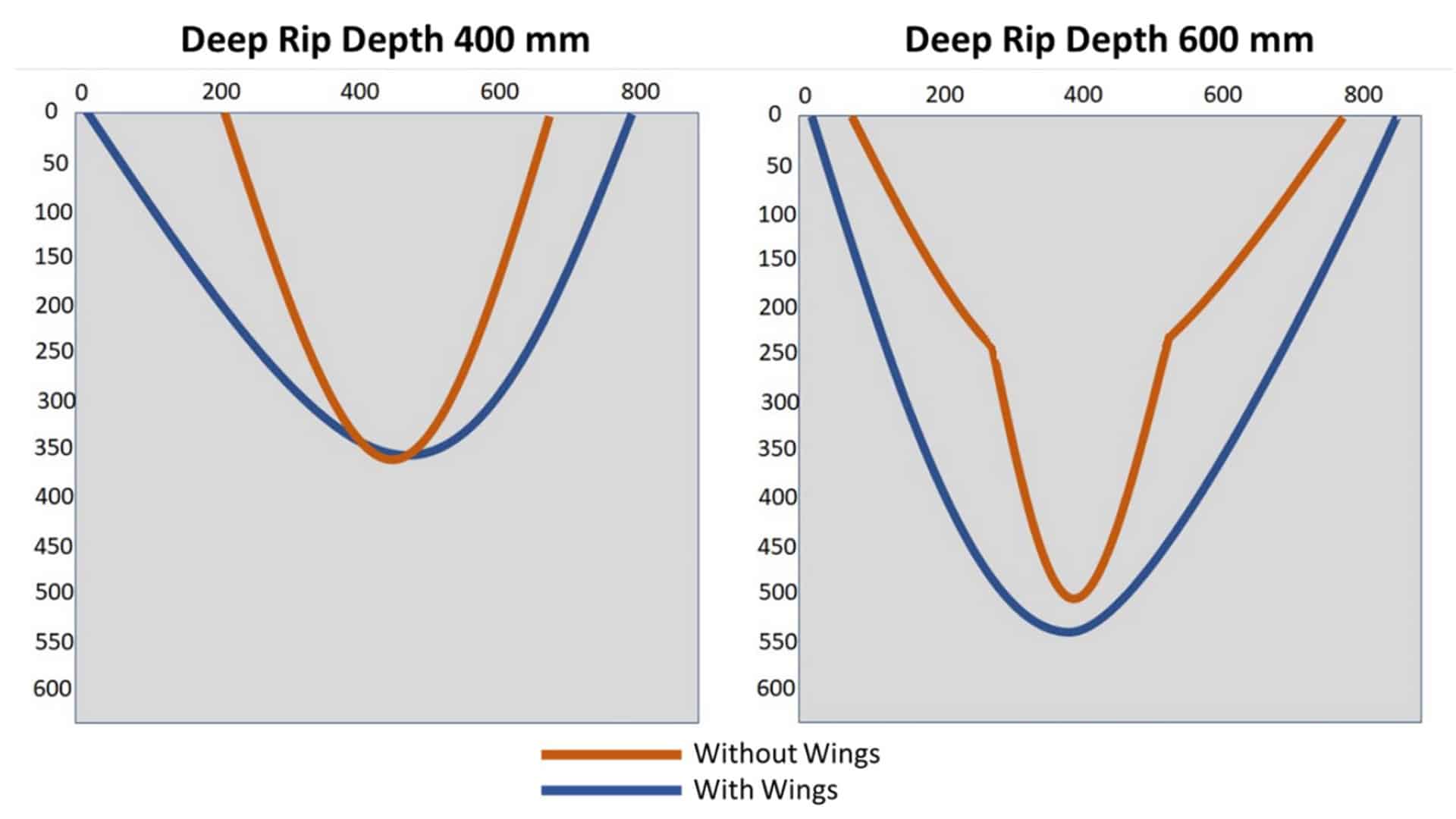

To assess soil loosening, 50m by 4m wide test strips were ripped at depths of 400mm and 600mm, and straight legged tynes were compared with using winged tynes.

The yield benefit of soil loosening was then assessed at Caliph (2019) and Woodleigh (2020). The 2019 trials suffered drought conditions and a wider range of tyne spacings and ripping depths were assessed at Woodleigh the following year, including depths of 300mm, 450mm and 600mm and tyne spacings of 0.5m, 0.75m and 1m. An additional treatment with winged tynes was ripped to 450mm. These plots were planted to barley in the first year, followed by wheat.

Adding an organic amendment (chicken litter) to the soil was assessed in trials at Younghusband in 2021, with comparisons between surface spreading to unimproved and ripped soils, and with passive inclusion during amelioration.

Finally, to measure and improve the trafficability, a Landcruiser ute was driven across ripped paddocks at Pinnaroo in 2020, and the depth of the wheel ruts was measured. The depth and emergence of wheat sown for these tests was also assessed.

Results

Working at 400mm, a straight legged tyne loosened a cross sectional area of 0.26m2. This nearly doubled to 0.44m2 when depth was increased to 600m. Adding a wing at this depth increased the loosened area by about 50 per cent more while requiring just 24 per cent more force.

Even with only 100mm of rainfall at Caliph in 2019, a yield benefit of 0.6t/ha was observed from the soil loosening achieved by ripping at 600mm with tyne spacings of 0.8m or less.

At Woodleigh in 2020, a yield benefit of 1.2t/ha (50 to 60 per cent) was achieved in plots ripped to 450mm or 600mm with 450mm tyne spacing. Similar gains resulted from 750m spacings at 600mm depth, or 450mm with wings. All other configurations provided less benefit.

The best responses had subsequent-year yield benefits of 15 to 17 per cent.

At Younghusband in 2021, a barley yield of less than 1t/ha was improved to 2.5t/ha by spading and 3t/ha by deep ripping. Using inclusion plates did not affect yield.

Applying 5t/ha of chicken litter improved yield by a further 0.25t/ha on control plots, 0.56t/ha with deep ripping and 0.70t/ha with deep ripping using inclusion plates. A second inclusion plate treatment where chicken litter was directly injected into the void behind the tyne provided a 1.5t/ha yield benefit.

In trafficability trials, the Landcruiser left 20mm to 30mm ruts in control plots, while ruts in ripped soils were up to 120mm deep. Rolling reduced rut depth by 50 per cent.

Wheat seeds emerged from 20mm to 30mm depth in unripped and ripped + rolled paddocks, and from 50mm to 60mm depths in ripped but unrolled paddocks.

Project Participants

Mallee Sustainable Farming: Tanja Morgan

Frontier Farming Systems: Michael Moodie

UniSA: Chris Saunders, Jack Desbioles

Growers: Wade and Chad Nickolls (Pinnaroo), Michael Lange (Woodleigh), James Stephens (Younghusband).

The Problem

Deep ripping has demonstrated strong benefits on sandy soils, however the wide range of setup parameters makes maximising benefits challenging.

The research

Trials were conducted to establish and publish technical guidelines for growers wishing to successfully ameliorate Mallee sandy soils.

More information

Tanja Morgan, Mallee Sustainable Farming

T: 0429 395 918

Value for Growers

This project has developed useful soil amelioration guidelines for growers on the often-challenging deep sandy soils of the Mallee. Extension outputs included six videos, two virtual tours, seven update presentations (201 attendees), and five field walks (165 attendees).

The technical information has also been summarised in a deep ripping factsheet, to help growers access localised best practice information. This will help farmers maximise productivity, sustainability and profitability.

Latest Research Projects