START

FINISH

Summary

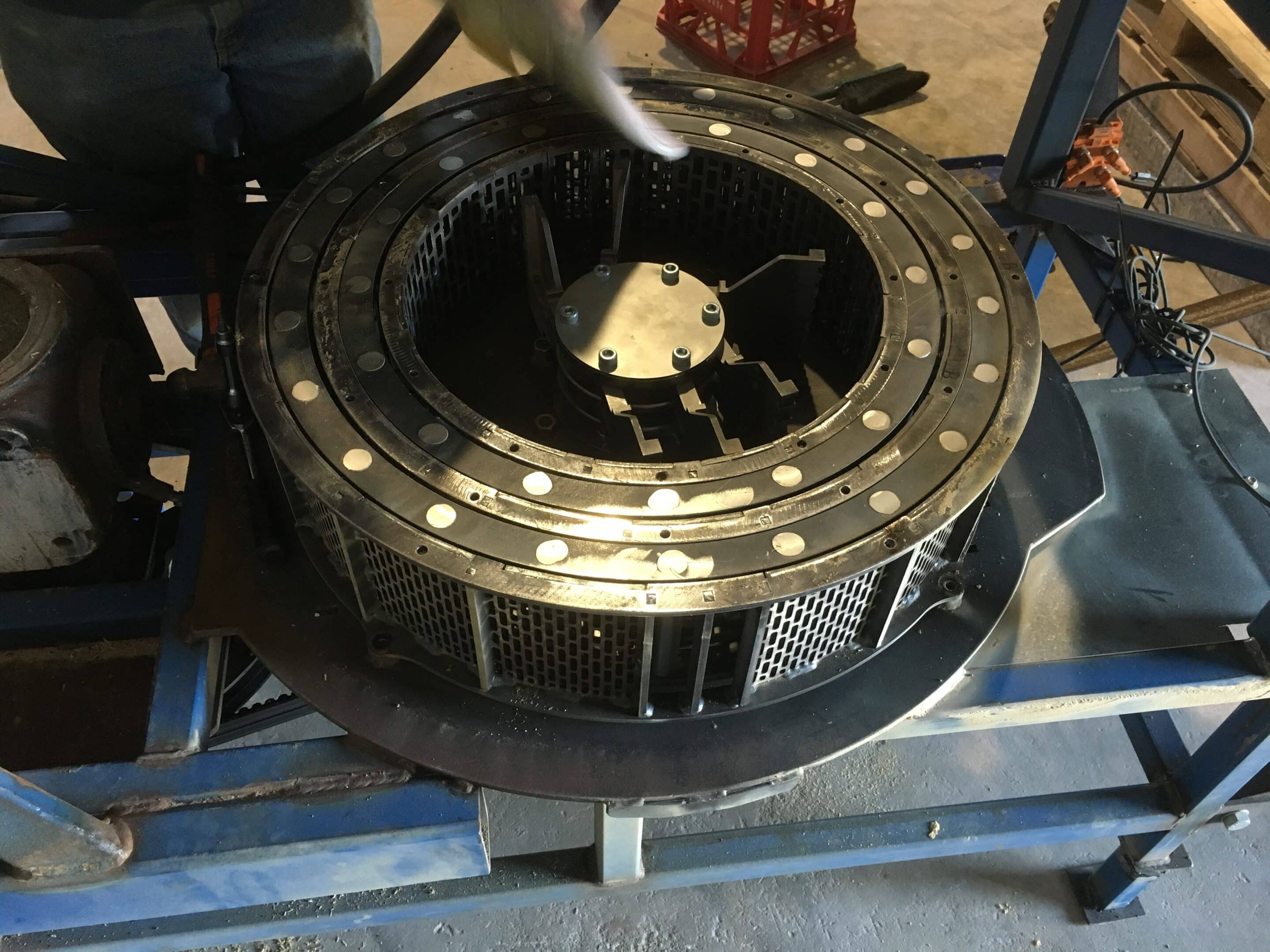

Recommendations were needed for growers to assess the costs and benefits of using the harvest weed seed control attachment Seed Terminator in SA cropping enterprises. Stationary and field tests were conducted to determine optimum mill settings for maximum control of the most common weeds in SA and to determine associated power consumption and resulting costs.

Weed kill efficacy and operating costs were calculated using a combination of stationary and field tests. Operating costs in different crops and conditions were calculated and the sensitivity of operating cost to farm scale and grain yield assessed.

Background

Research was needed to determine optimum operational settings for Harvest Weed Seed Control (HWSC) of common SA weed species using Seed Terminator. This project explored control efficacy and power requirements to operate the mill.

Power requirements are affected by harvester size, harvest rate and current engine load. The project also explored how farm size and average grain yields impact on ownership and operating costs.

Research Aims

Project core objectives were to:

- Determine optimum mill settings to kill seeds of key SA weed species.

- Determine power consumption and associated cost to operate at these settings.

- Assess the efficacy of Seed Terminator in the field.

- Provide recommendations for cost effective operation of Seed Terminator in SA.

In The Field

Stationary lab trials were used to determine optimal Seed Terminator settings for effective destruction of common weed seeds, including annual ryegrass, wild radish, brome grass, wild oats, bifora, bedstraw, marshmallow, burr medic, tare, wheat and lentil.

The stationary trials were also used to evaluate power required to process material using the torque transducer, supplied by Seed Terminator.

Three field trials were established to target selected weeds during harvest 2017: wheat at Pinnaroo, windrowed barley at Stansbury; and lentils at Maitland. Measurements were taken using the onboard harvester operating screen and yield monitoring software.

Processed weed samples from stationary trials were tested for germination viability by the University of Adelaide team and weed emergence was counted.

Data from the above was combined and assessed for a detailed cost benefit analysis of the technology.

Results

Seed Terminator was effective at controlling more than 98 per cent of 9 of 13 weed species in the stationary tests. Of the other weed species tested, 87.5 per cent of burr medic was controlled, and 82 per cent of marshmallow controlled when the mill was operated at maximum speed (3000RPM). The remaining two species did not germinate in the control treatments.

Differences in mill settings such as RPM, feed rate and screen orientation had little impact on most species when used within the normal operating range. Reducing RPM did reduce efficacy for some species such as ryegrass and marshmallow. Increasing mill speed to 3000 RPM increased emergence of burr medic, likely due to the thrashing and scarifying effect and this needs more investigation.

Stationary testing showed that Seed Terminator should be run at the minimum speed necessary to provide adequate weed control and unhindered flow of material. Power requirements increased significantly when RPM and inward flow were increased.

Data on harvester power and speed collected during field trials showed the mills were adding significant load to the harvester. Increases in fuel requirements ranged from 0.37 – 1.22 L/t depending on crop type. Reduction in harvest speed was found to be significant, with harvest rate reduced by 16 per cent and 32 per cent when the mill was engaged in wheat and lentils respectively.

Farm size and average grain yields have a significant impact on Seed Terminator ownership and operating costs. In a business with 1500ha of cropping with a cereal legume rotation, the mill will cost around $23.9/ha, assuming a 10 per cent reduction in harvest rate. Ownership costs are reduced when operated over more hectares, while operating costs increase with increasing grain yield. Costs are highly sensitive to impacts on harvester capacity and these are influenced by harvester size, harvest rate and current engine load. A calculator was produced to explore these scenarios in more detail and is available from Trengove Consulting. (See ‘More information’ above.)

Project Participants

Trengove Consulting: Sam Trengove, Stuart Sherriff, Matthew Hewett, Jordan Bruce, Andrew Bird.

Seed Terminator: Nick Berry.

University of Adelaide, Weed Research Group: David Brunton, Peter Boutsalis, Gurjeet Gill, Chris Preston.

Field trial: Wade and Chad Nickolls, Nigel and Caroline Roenfeldt.

The Problem

Data was needed to determine the most effective operating settings and associated power consumption for use of the Seed Terminator to control South Australian weed species through mechanical pulverisation.

The research

Weed kill efficacy over a range of mill settings and power consumption of the Seed Terminator were measured in stationary operating and field tests.

Tests focussed on annual ryegrass, wild radish, brome grass, wild oats, bifora, bedstraw, marshmallow, Indian hedge mustard, wild lettuce, burr medic and tare.

Field trials conducted to target selected weeds in wheat at Pinnaroo, windrowed barley at Stansbury; and lentils at Maitland during harvest 2017.

More information

Sam Trengove, Trengove Consulting

T: 0428 262 057

E: [email protected]

Value for Growers

This research demonstrates that Seed Terminator has high levels of activity on most key weeds tested, and growers can have confidence the technology is fit for purpose. Detailed costing, including a better understanding of impacts on harvest capacity, will enable growers to make informed decisions using independent data and this decision making should consider current harvester engine capacity.

Latest Research Projects